How do we make chocolate?

From bean to bar, every step of our process is carefully considered to bring out the best possible flavour in our chocolate. We work slowly, thoughtfully, and as purely as possible.

In the country of origin

Fermentation

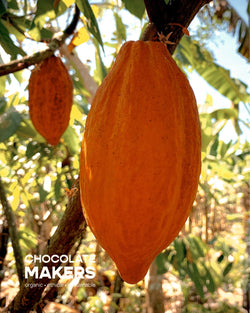

Fermentation is the very first step in developing the flavour of chocolate and takes place in the country of origin, immediately after harvest. After the cocoa pods are opened, the beans are placed into wooden boxes. These boxes are initially closed, limiting oxygen exposure.

In the first phase, yeasts and bacteria convert the sugars in the pulp into alcohol. In the second phase, the boxes are opened, allowing oxygen in, and the alcohol is transformed into acids. The temperature of the beans rises, their colour changes, and the foundations of chocolate flavour are formed.

This natural process takes about six days and is crucial for the final taste and quality of the chocolate. Without proper fermentation, even the best cocoa beans cannot develop their full flavour potential.

In the country of origin

DRYING

After fermentation, the beans are dried. Drying is essential to stop the fermentation process and to reduce moisture levels, preventing mould and spoilage during transport.

This sun-drying process takes approximately two and a half weeks and plays a key role in preserving the flavours developed during fermentation. Careful drying is therefore vital for both quality and taste, ensuring the beans arrive at our factory in optimal condition.

In the factory

Roasting

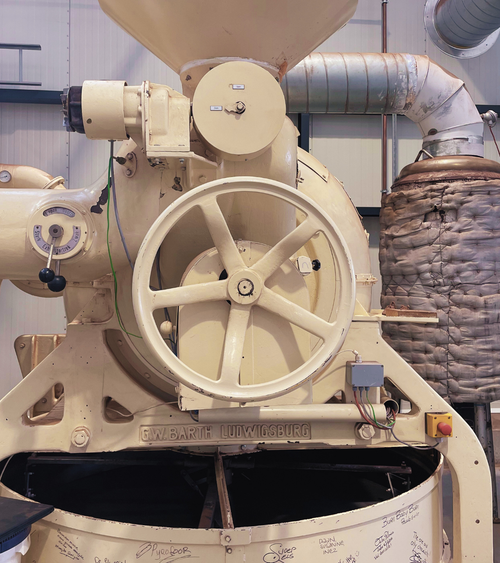

The first step in our factory is roasting the cocoa beans, one of the most important stages for flavour development. We use an antique Sirocco 400 Ball Roaster from 1930.

Each cocoa origin has its own unique roast profile to achieve the optimal aroma. By roasting the whole bean, rather than just the nibs, we achieve a deeper, more complex flavour than the faster, more common nib-roasting method.

.

- Did you know? Our Roastmaster checks the beans during roasting by taking samples and knows exactly when they are perfectly roasted.

In the factory

Winnowing

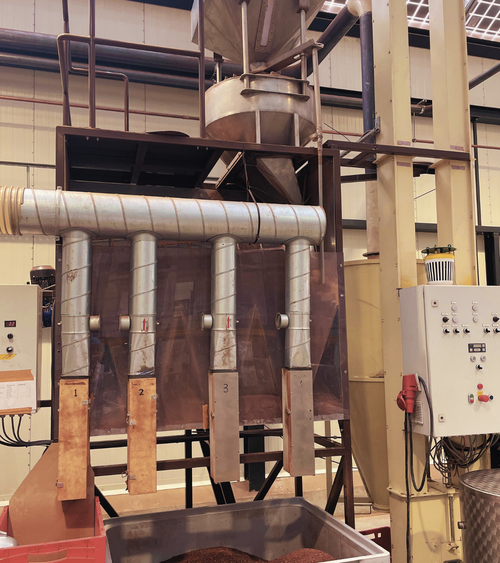

Once roasted, the beans are cracked and winnowed in our custom-built winnower. The beans are broken open, separating the cocoa nibs from the shells. The lighter shells are extracted, while the nibs fall into a collection bin below. These nibs are the heart of our chocolate.

.

- Did you know? Our cocoa shells are being reused, for example to make cocoa tea.

In the factory

Grinding

Cocoa nibs consist of about 55% cocoa butter. Through grinding and gentle heating, the cocoa butter is released and the nibs transform into a liquid known as cocoa mass. During this process, unwanted acids (such as vinegar-like notes) evaporate. Grinding nibs into cocoa mass takes approximately eight hours.

In the factory

Mixing & Conching

To create chocolate, we add sugar and some cocoa butter to the cocoa mass. For milk chocolate, we also add milk powder. All ingredients are carefully selected and used according to our own recipes, kept as pure as possible, with minimal added sugar.

This process takes place in our ball mills: we have one for dark and one for milk chocolate. Here, the ingredients are thoroughly mixed and finely refined. The chocolate is then conched, a process that significantly enhances smoothness and flavour development.

STORAGE

Once the chocolate has reached the desired flavour and texture, the liquid chocolate is transferred to storage tanks. These tanks are kept at around 40°C, ensuring the chocolate remains liquid and ready for moulding.

In the factory

Tempering, Moulding & Cooling

From the storage tanks, the chocolate is pumped into the moulding machine. During this step, the chocolate follows a precise temperature curve, known as tempering, which gives it the correct structure, snap, and shine.

MOUDLING & COOLING

After tempering, the liquid chocolate is poured into moulds. The filled moulds are placed on a vibrating table to evenly distribute the chocolate and remove air bubbles. They then pass through a cooling tunnel, allowing the chocolate to set and release cleanly from the mould.

In the factory

Packaging

We wrap our chocolate bars in biobased, compostable packaging. Each bar is printed with a best-before date and batch code. After a final quality check, the bars are stored at a constant temperature, ready for sale.